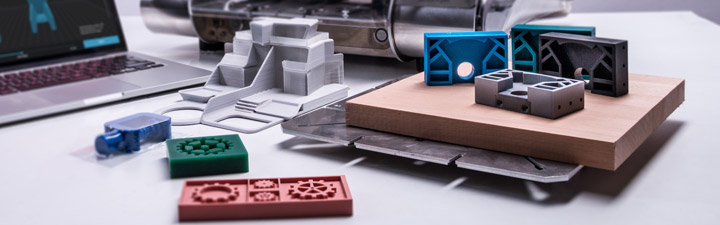

What You Can Get Out of 3D Printing Your Robot If you’re…

Seattle 3D Printing

The Advantages of using ABS in 3D Printing

What’s ABS and what can it do? ABS is acrylonitrile butadiene styrene,…

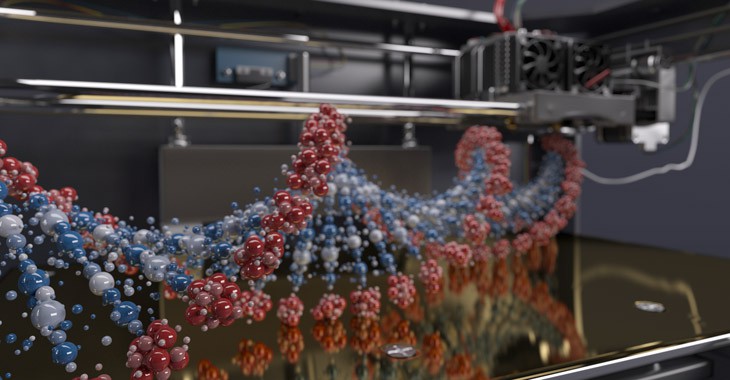

3D Printing with Graphene

Graphene is one of the most revolutionary materials ever developed. This carbon…

3D Printing Possibilities Today: From Small to Massive

Amazing Things 3D Printing Has Made Scientists, thinkers, designers, engineers, and a…

The Rise of An Entire 3D-Printed Village: First in the World

3D Printed Shelters for Everyone Yves Behar is a Swiss designer, entrepreneur…