ULTEM™ 9085

Material Data Sheet

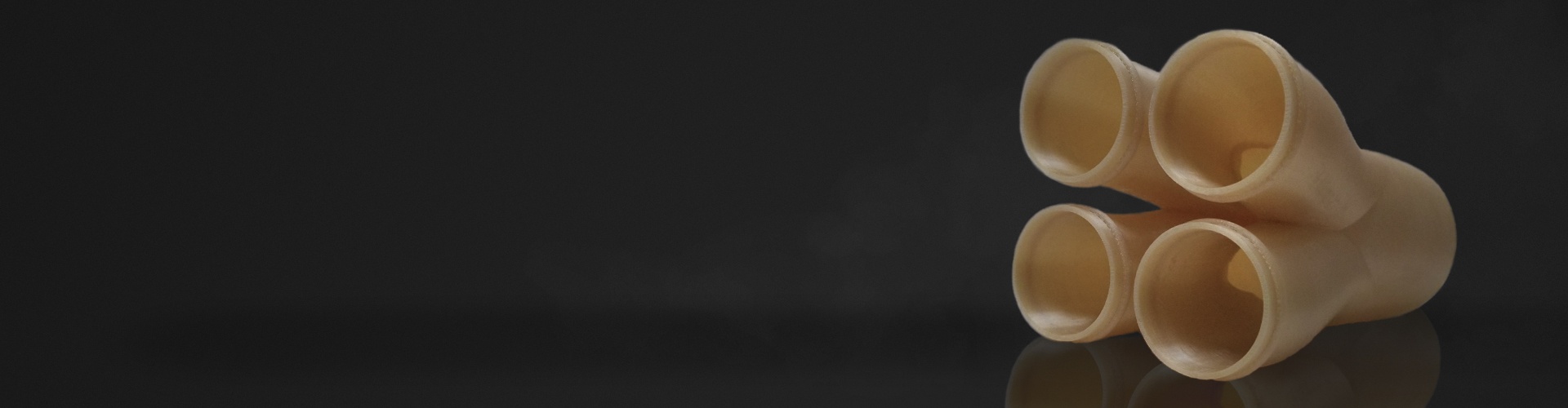

Ultem™ 9085

Ultem™ 9085 is a flame retardant high performance thermoplastic for direct digital manufacturing and rapid prototyping. It is ideal for the transportation industry due to its high strength-to-weight ratio and it FST (flame, smoke, and toxicity) rating.

This unique material’s preexisting certifications make it an excellent choice for the commercial transportation industry – especially aerospace and ground vehicles. Ultem 9085 allows design and manufacturing engineers to produce fully functional parts that are ideal for advanced functional prototypes or end use without the cost or lead time of traditional tooling.

Color options:

Black and Tan

Quick Facts:

- High strength-to-weight ratio

- Flame retardant

- Excellent for aerospace and ground vehicles

| Mechanical Properties | Test Method | English | Metric |

|---|---|---|---|

| Tensile Strength (Type 1, 0.125”, 0.2”/min) | ASTM D638 | 10,400 psi | 71.6 MPa |

| Tensile Modulus (Type 1, 0.125”, 0.2”/min) | ASTM D638 | 322 kpsi | 2,200 MPa |

| Tensile Elongation (Type 1, 0.125”, 0.2”/min) | ASTM D638 | 6% | 6% |

| Flexural Strength (Method 1, 0.05”/min) | ASTM D790 | 16,700 psi | 115.1 MPa |

| Flexural Modulus (Method 1, 0.05”/min) | ASTM D790 | 362.6 kpsi | 2,500 MPa |

| IZOD Impact, notched (Method A, 23°C) | ASTM D256 | 2.0 ft-lb f/in | 106 J/m |

| IZOD Impact, un-notched (Method A, 23°C) | ASTM D256 | 11.5 ft-lb f/in | 613.8 J/m |

| Compression Strength | ASTM D695 | 15.2 ksi | 104 MPa |

| Compression Modulus | ASTM D732 | 280 ksi | 1930 MPa |

| Shear Strength (0.25” thick coupon) | ASTM D732 | 8.3 | 57 MPa |

| Thermal Properties | Test Method | English | Metric |

|---|---|---|---|

| Heat Deflection (HDT) @ 66 psi, 0.125” unannealed | ————– | ————– | ————– |

| Heat Deflection (HDT) @ 264 psi, 0.125” unannealed | ASTM D648 | 307° F | 153° C |

| Glass Transition Temperature (Tg) | DSC (SSYS) | 367° F | 186° C |

| Coefficient of Thermal Expansion | ASTM E228 | 3.67e-05in/(in∙F°) | 65.27 μm/(m∙C°) |

| Melting Point | ————— | Not Applicable | Not Applicable |

| Electrical Properties | Test Method | Value Range |

|---|---|---|

| Volume Resistivity | ASTM D257 | 4.9e15 – 8.2e15 ohm-cm |

| Dielectric Constant | ASTM D150-98 | 3.2 – 3.0 |

| Dissipation Factor | ASTM D150-98 | .0027 – .0026 |

| Dielectric Strength | ASTM D149-09, Method A | 290 – 110 V/mil |

| Other | Test Method | Value |

|---|---|---|

| Specific Gravity | ASTM D792 | 1.34 |

| Rockwell Hardness | ASTM D785 | —- |

| Flame Classification | UL94 | V-0 |

| Oxygen Index | ASTM D2863 | 0.49 |

| Vertical Burn | FAR 25.853 (Test a,60s, passes at) | 2 seconds |

| FAA Flammability | FAR 25.853 (Method A/B) | < 5 |

| OSU Total Heat Release (5 min test) | FAR 25.853 | 36 kW/m-2 |

| OSU Total Heat Release (2 min test) | FAR 25.853 | 16 kW min/m-2 |

| UL File Number | ————– | E345258 |

| Outgasssing | Test Method | Value |

| Total Mass Loss (TML) | ASTM E595 | 0.41% (1.00% maximum) |

| Collected Volatile Condensable, Material (CVCM) | ASTM E595 | -0.1% (0.10% maximum) |

| Water Vapor Recovered (WVR) | ASTM E595 | -0.37% (report) |

| Fungus Resistance (Method 508.6) | MIL-STD-810G | Passed |

| Burn Testing | Test Method | Value |

| Vertical Burn (60 sec) | FAR 25.853 | Passed (0.040” – 0.250” thick) |

| Heat Release 65/65 | FAR 25.853 | Passed (<40HR Peak, 0.060” thick) |

| NBS Smoke Density (flaming) | ASTM F814/E662 | Passed |

| NBS Smoke Density (non-flaming) | ASTM F814/E662 | Passed |