Applications

Let 3D Composites maximize your 3D printing experience.

See additive manufacturing at work

Discover and fix design errors early. Reduce costs for prototyping and tooling. Shorten project cycles. No matter the complexity we’ll help you get it done. See real world examples of how your ideas can be accomplished with 3DC.

Test Functionality & Design

3D printing allows for multiple prototypes that help verify design ergonomics and function elements that may not always be identifiable in a CAD drawing, so you can discover and fix errors early.

See Komo 4 News coverage of Everett High School students working with 3DC to practice their engineering skills.

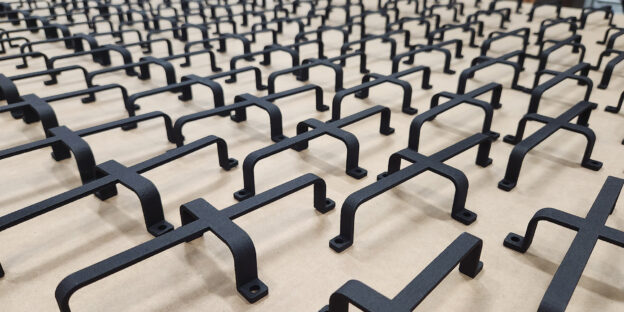

Confirmed Quality Production

Usable, finished parts can be produced for low volume production runs or single part projects. Parts can be made to fit different strength requirements and specifications.

3D Composites verifies the quality and conformity of products during all phases of the manufacturing process.

Quickly Produce Custom Parts

3D printing can be faster, more flexible, and less expensive when producing relatively small quantities of parts, giving your engineers the ability to produce parts and concept models immediately!

See how Rapid Prototyping made a quick job helping Nasty Jack’s Candy Company.