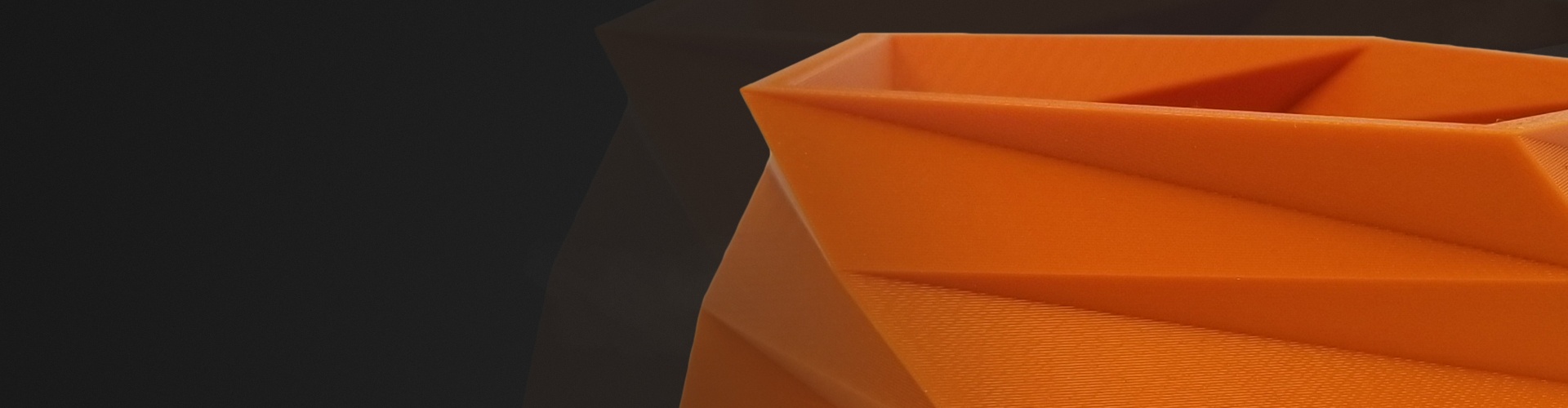

ABSplus™-P430

Material Data Sheet

ABSplus™-P430

ABSplus is a true production-grade thermoplastic that is durable enough to perform virtually the same as production parts. When combined with Design Series 3D Printers, ABSplus is ideal for building 3D models and prototypes in an office environment.

Color options:

Ivory, White, Black, Dark Grey, Red, Blue, Olive, Green, Nectarine, Fluorescent Yellow

Quick Facts:

- Production grade thermoplastic

- Durable and long-lasting

- Great for usable parts

| English | Metric | ||

|---|---|---|---|

| Mechanical Properties | Test Method | XZ Axis | XZ Axis |

| Tensile Strength, Ultimate (Type 1, 0.125”, 0.2”/min) | ASTM D638 | 4,700 psi | 33 MPa |

| Tensile Strength, Yield (Type 1, 0.125”, 0.2”/min) | ASTM D638 | 4,500 psi | 8 MPa |

| Tensile Modulus (Type 1, 0.125”, 0.2”/min) | ASTM D638 | 320,000 psi | 2,200 MPa |

| Tensile Elongation at Break (Type 1, 0.125”, 0.2”/min) | ASTM D638 | 6% | 6% |

| Tensile Elongation at Yield (Type 1, 0.125”, 0.2”/min) | ASTM D638 | 2% | 2% |

| IZOD Impact, notched (Method A, 23°C) | ASTM D256 | 2.0 ft-lb/in | 106 J/m |

| English | Metric | ||||

|---|---|---|---|---|---|

| Mechanical Properties | Test Method | XZ Axis | ZX Axis | XZ Axis | ZX Axis |

| Flexural Strength (Method 1, 0.05”/min) | ASTM D790 | 8,450 psi | 5,050 psi | 58 MPa | 35 MPa |

| Flexural Modulus (Method 1, 0.05”/min) | ASTM D790 | 300,000 psi | 240,000 psi | 2,100 MPa | 1,650 MPa |

| Flexural Strain at Break (Method 1, 0.05”/min) | ASTM D790 | 4% | 4% | 2% | 2% |

| Thermal Properties | Test Method | English | Metric |

|---|---|---|---|

| Heat Deflection (HDT) @ 66 psi | ASTM D648 | 204°F | 96°C |

| Heat Deflection (HDT) @ 264 psi | ASTM D648 | 180°F | 82°C |

| Glass Transition Temperature (Tg) | ASTM D650 | 226°F | 108°C |

| Melting Point | – – – – – – – | Not Applicable | Not Applicable |

| Coefficient of Thermal Expansion | ASTM E831 | 4.90E-05 in/in/°F | 8.82E-05 mm/mm/°C |

| Electrical Properties | Test Method | Value Range |

|---|---|---|

| Volume Resistivity | ASTM D257 | 2.6E15 – 5.0E16 ohm-cm |

| Dielectric Constant | ASTM D150-98 | 2.3 – 2.85 |

| Dissipation Factor | ASTM D150-98 | 0.0046 – 0.0053 |

| Dielectric Strength | ASTM D149-09, Method A, XZ Orientation | 130 V/mil |

| Dielectric Strength | ASTM D149-09, Method A, ZX Orientation | 290 V/mil |

| Other | Test Method | Value |

|---|---|---|

| Specific Gravity | ASTM D792 | 1.04 |

| Flame Classification | UL94 | HB (0.09”, 2.50mm) |

| UL File Number | – – – – – – – | E345258 |

| Rockwell Hardness | ASTM D785 | 109.5 |

Download pfd for technical specifications.