Aerospace: Big Customer for 3D Printing

The aerospace industry is always innovating. It is one of the sectors that is always ahead or is an early adopter of latest inventions in technology. It is also the ultimate trendsetter in manufacturing technology. Hence, it is no surprise that aerospace is a heavy market for 3D printing, the technology that is changing the face and the pace of almost anything manufacturing.

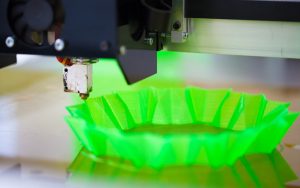

3D printing, also called Additive Manufacturing, answers some of the main challenges of aerospace, such as environmental performance restrictions of which aviation and aerospace have plenty of. Aerospace engineers find Fused Deposition Modeling (FDM) technology the most reliable technique for prototyping, tooling and part manufacturing. FDM is compatible with high-performance thermoplastics to build jigs, fixtures, check gauges and end-use parts that are resistant to moisture, high temperature changes, chemical and UV exposure, and other environmental hazards.

The development process and time-to-market is significantly shortened by 3D printing. Engineers can test multiple designs very quickly, change them to fit customer specifications and minimize product launch risks. It eliminates or minimizes the cost for expensive and poorly amortized tooling. It surely is a cost-effective component of aerospace R&D. 3D printing allows the freedom to design the complex geometries of aerospace craftsmanship without increasing cost.

It maximizes the flexibility of components, allowing for exploring of new designs, making them simplified and consolidated and improving reliability and durability. Components to be light-weight due to efficient geometry that carves out unnecessary material. Resultant parts improve fuel economy because the craft is lighter; that leads to lower fuel consumption and less CO2 emissions that impact the environment.

3D Composites Seattle Staying Up to Speed

What used to require welding together 20 parts now requires printing just one. Such is the advantage offered by your 3D printing company in Seattle. 3D Composites is your reliable printer, serving Seattle’s aerospace community for many years now.