The Amazing Graphene

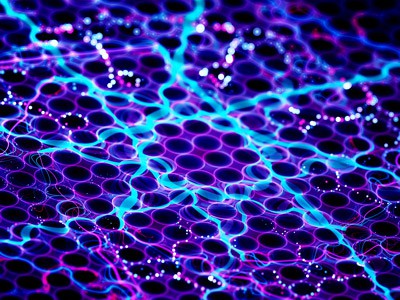

See this thin, single layer of tightly packed carbon atoms bonded together in a hexagonal form, looking like a slice of honeycomb lattice? It’s called graphene. It is the thinnest, lightest, yet strongest material known to man, even 100 to 300 times stronger than steel.

It is the best conductor of heat at room temperature and the best conductor of electricity. Carbon, being the second most abundant mass in the human body and the 4th most abundant element in the universe, therefore, makes graphene a totally ecologically-friendly and bio-sustainable material that bears almost a limitless number of applications.

And so how is graphene used? It has made huge gains in the electronics and biotechnology industries, in a restricted sense, though. That is because to produce high quality graphene entails a very expensive and complicated process, using very toxic materials at high temperatures. To grow graphene layers, referred to as graphite, was difficult. On a large scale, it was impossible. Separating the graphene layers from its metallic substrate can potentially damage the graphene itself. So it limited its electronic applications.

Studies, however, pushed the possibility of safer molecular electronics by more effective separations. Yet, the quality of the graphene is still the limiting factor in technological applications. Supercapacitors, which are high-capacity energy storage solutions, are the best applications of graphene so far.

That may change soon. Graphene has been creating a buzz in the 3D industry. Researchers at Rice University and Tianjin University have broken ground by 3D printing atomically thin graphene in ultra-small pieces. There is the potential to bulk produce graphene in amounts useful for industrial applications.

The process uses nickel and powdered sugar and adapting a laser-based 3D printing technique create small blocks of graphene foam. The process did not use molds nor high temperatures. The graphene foams produced were lightweight and low density with large pores that make up 99 percent of its volume.

3D Printed Graphene Applications

3D-printed graphene foams show promise for various applications. It can mega-speed up web uploads; It can all charge up a cellphone in 5 minutes and potentially can clump together radioactive waste to make disposal easier. Graphene filters can make salt water safe for consumption as its holes are big enough for water to pass through, yet small enough to catch salt. It can make touchscreens unbreakable as a conductor in plastics rather than glass. High-power graphene supercapacitors would make batteries obsolete. Finally, it can be incorporated in bionic devices in neurologic living tissues.

Have an idea? 3D Composites can make it happen!

Know more about the world’s strongest material that can be 3D printed over at our 3D printing company in Seattle. If you’ve got an idea, tell us about it. It might be the next best thing to buzz about.