What 3D printing process is best for your industry? Whether you are designing a huge tooling mold or need to do a run of hundreds of fingernail sized parts, we can print it. It’s a new year and our team and 3D Composites wanted to share with you our thoughts on which of our additive manufacturing processes we can provide for you in 2023.

FDM is still on top for Aerospace

The 3D printing market is growing at an amazing rate, with new technologies and processes continually expanding what can be done for manufacturing. However, it takes time for these processes and materials to meet the test requirements that are necessary for aerospace industry certifications. The FDM printing process has maintained its position because of the high-grade thermoplastic materials options that can meet the requirements of common aerospace standards such as flammability, strength, and durability.

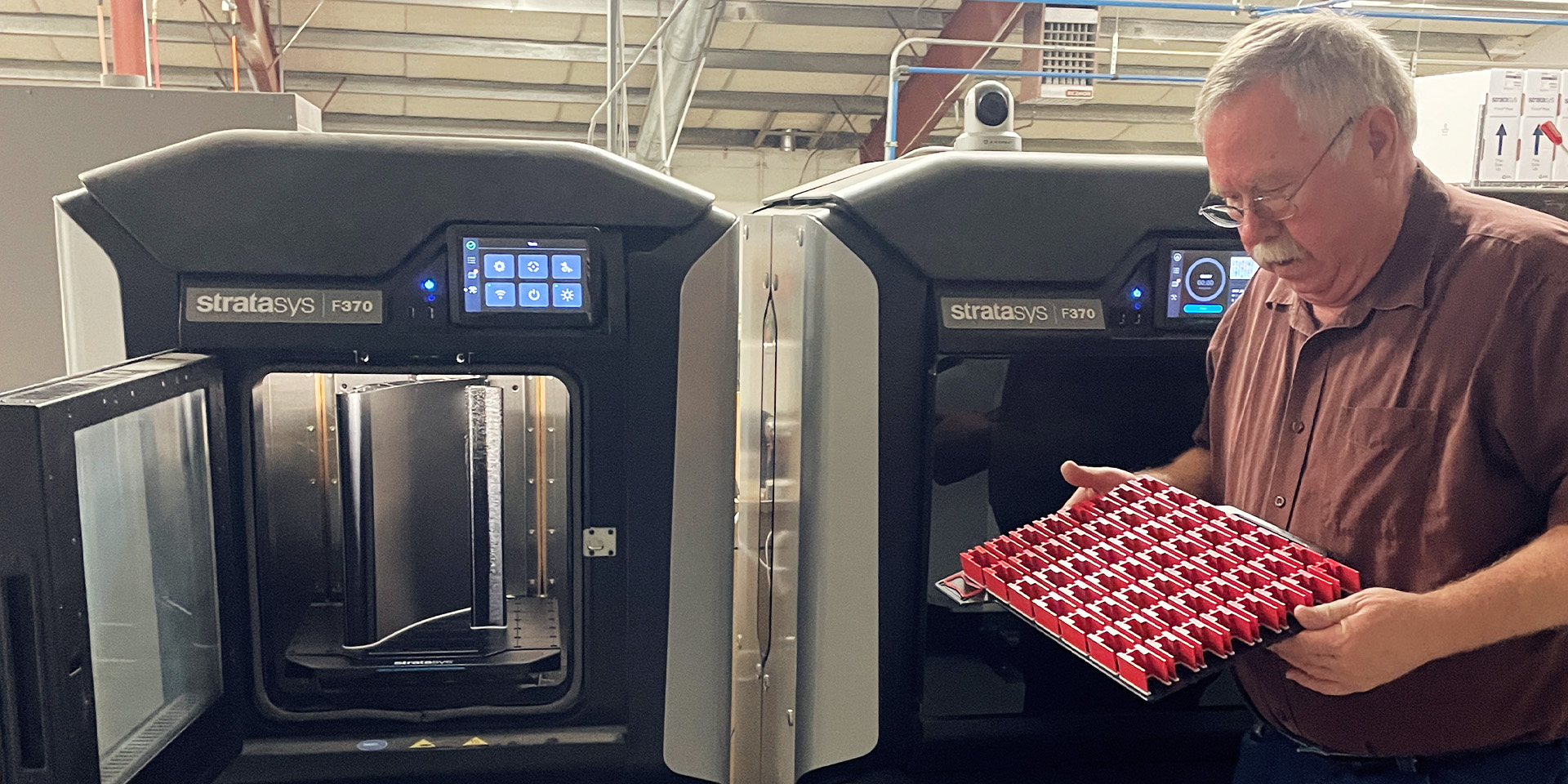

FDM is also a great source for concept modelling and tooling. If you know your project will be printed in FDM you can work from a highly accurate prototype for relatively low costs. Heat resistant materials like Ultem 1010 can withstand thermoforming and autoclaving, making low cost tooling for short production runs accessible to smaller development teams. FDM manufactured parts can also span a greater surface area than other additive manufacturing process because it can keep complex geometries on a small scale while also being able to withstand bonding of oversized builds. Last year 3DC printed over 20,000 FDM aerospace parts for our customers and 2023 will see even more.

High-volume Production & Prototyping with SAF

For us, end use parts don’t stop at aerospace, however. This year our reach has expanded to providing higher volume production runs that will benefit any industry. The selective absorption fusion (SAF) process allows for small part production at a higher rate than previously available to us, yielding repeat parts quickly while still leaving room for customized prototypes. The surface finish of SAF parts can be more aesthetically pleasing than FDM parts, and while Ultem 9085 is still the leader for fly-away parts and Ultem 1010 for high-tempurature tooling, SAF PA12’s mechanical properties give it the rigidity and thermal control for repeatable output. We have found that customers who print items such as medical accessories and industrial caps and fittings have made the switch to SAF because they can get consistent quality at a reduced rate.

We can help you begin

Even as the technology continues to develop, the future of 3D printing and additive manufacturing still offers comparatively sustainable practices and lower costs. Efficient processes and customized solutions can give you the most out of your design. Contact us for more information on what 3D printing processes would be best for your project.