What’s ABS and what can it do?

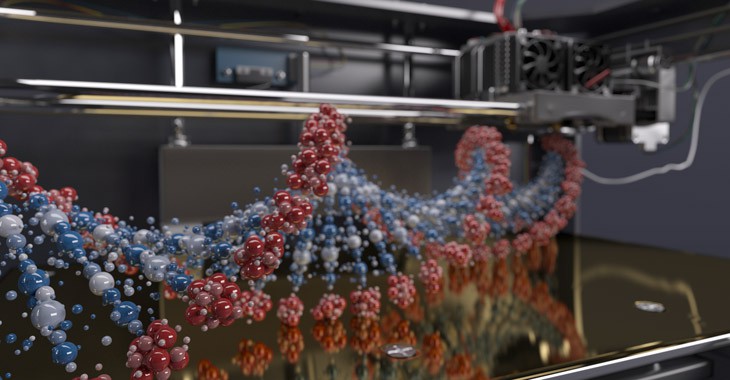

ABS is acrylonitrile butadiene styrene, a thermoplastic material that is easily sculpted and molded when superheated, allowing to form different shapes in accordance with the computer-assisted design. As it cools down, it conforms to the shape of the object being printed. ABS is a strong and sturdy material and ideal for professional applications, such as plastic car parts.

There are variants of ABS that make it ideal material for particular types of need.

The ABS-ESDTM has anti-static properties that prevents outside elements to stick to the object being printed, like powder, dust, and other fine particles. This property enables cleaner and smoother surfaces of the object or model and good for the assembly of electronic components, and also for casings and packaging.

The ABS M30, compared to the standard ABS, has greater tensile strength and stronger layer bonding, making for more realistic and durable parts of manufacturing tools and end-use parts for automotive and aviation industries. On the other hand, the ABS M30i is high- strength and suitable for medical, pharmaceutical and food packaging uses, being biocompatible and easily sterilized.

The ABSplusTM-P430 is the durable, true production-grade thermoplastic used for prototyping and building 3D models in an office setting. For industrial use, the PC ABS combines the properties of both materials – the superior strength and heat resistance of polycarbonate and ABS flexibility. It is ideal for automotive, electronics, and telecommunication utility.

Trusting ABS for 3D Printing in Seattle

The choice of any of these ABS variants for their most suitable use in 3D printing makes for superior quality models or prototypes here at our Seattle company. 3D Composites puts a high premium on product quality and customer satisfaction.