The History of 3D Printing

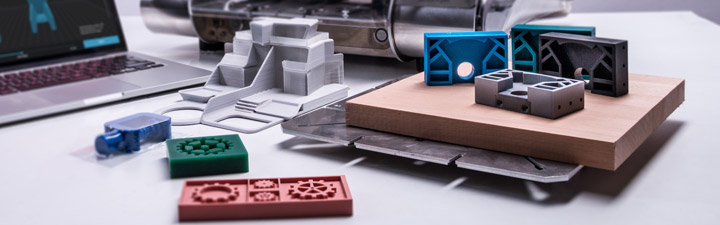

3D printing technology was first called Rapid Prototyping (RP) back in the late 80’s. It was boasted as fast and cost-effective for building prototypes used in product development. A certain Dr. Kodama, Japanese patent lawyer, first filed the patent application in 1980, but for some reason, delayed in making it before the prescribed deadline. Hence, by 1986, Charles Hull, was issued the first patent for stereolithography apparatus. He first invented his SLA machine in 1983 and later co-founded 3D Systems Corporation. Today it is one of the largest and most prolific organizations in 3D printing.

Rapid Prototyping Technology

The corporation’s SLA process may be the first but it was not the only rapid prototyping technology at the time. In 1987, Carl Deckard of the University of Texas, filed a patent for the Selective Laser Sintering (SLS) RP process, which later on 3D Systems Corp. acquired. In 1989, Scott Crump, a co-founder of Stratasys Inc. filed a patent for Fused Deposition Modeling (FDM) which was issued in 1992. It is still in use today as well as the most preferred process of many entry-level printers now.

Europe was not to be left behind. So in 1989, Hans Langer founded EOS GmbH in Germany. The company also dealt in SLS in the beginning but its Research & Development refocused and later placed heavier emphasis on the laser sintering (LS) process with much vigor. Today, their systems are recognized worldwide for quality output for industrial prototyping and production applications of 3D printing.

During all these years, other 3D printing technologies and processes were emerging, namely Ballistic Particle Manufacturing (BPM), Laminated Object Manufacturing (LOM), and Solid Ground Curing (SGC). Other competing companies entered the field and the RP market grew in size in the 90’s. The three – 3D Systems, EOS and Stratasys – were the originals still in big business today.

From the 1990’s up until early 2000’s new technologies continued to be introduced, mostly on industrial applications and largely for prototyping applications. R&D was the focus of the more advanced technology providers. New terminologies begin to emerge, namely Rapid Tooling, Rapid Casting and Rapid Manufacturing. And then there’s Additive Manufacturing. Now it’s the accepted umbrella terminology for all things 3D printing due to the expansion of applications.

By the mid 90’s, distinct diversifications began to emerge. There’s high-end 3D printing, expensive but geared towards high value, highly engineered, complex parts. Applications expanded and covered aerospace, automotive, architectural, and medical, among others. Then there’s the lower market – the 3D printers in the mid range where a price war raged with some improvements in printing accuracy, speed and materials.

Stay tuned for the developments in 3D printing history when the 2000’s roll in our next blog.