Repairing In Zero Gravity

A joint effort of engineer-researchers from the University of Sydney and University of Science and Technology of China is proving that under simulated orbital conditions, high-temperature 3D printing is possible. There is a lack of heat transfer in space, and systems that use high-temperature will in themselves overheat. However, they proved that using a new 3D printer they developed with special controllers, it can be realized.

Did you know that more than 2,500 satellites have been orbiting the Earth in the last 70 years? These satellites are vital for navigation and communication with Earth, they guide space missions, and provide imaging, scientific surveying, and others. If they fail they can impede operations, throw it off-course, and do damage to other satellites or vehicles by the debris they may discharge. Hence, they need servicing from time to time or as needed. This is accomplished via on-orbiting manufacturing, which is less expensive than rocket missions being launched from Earth with all their repair equipment.

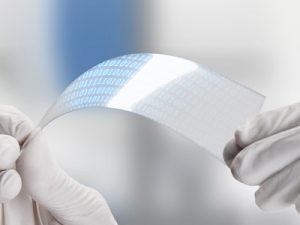

However, the cost of on-orbit manufacturing is becoming more costly, forecasted to reach $6.2 billion by 2030. The researchers aim to reduce the cost in this area by highlighting the success of their 3D printing experiments. Using FDM 3D printing, it’s possible to produce PEEK satellite spares in-orbit. PEEK plastic is one of the most utilized thermoplastic materials in aerospace. A newly developed 3D printer with Proportional Integral (PI) controllers is able to operate at up to 400°C in a vacuum, making it ideal for future orbital repair missions.

Thermal Control

Their prototype FDM 3D printer with an upgraded thermal control is complete with heat bar, block, sink, strap, extruder and radiator. With increased heat straps between the device’s heat sink and radiator, the temperature of its central tube is more effectively controlled, while preventing melted filament backflow during material feeding. They also introduced a PI control system that acts as a failsafe device designed to kick in at temperatures of 380°C, enhancing the precision of its thermal control features, but also preventing overheating and risking repair errors.

This is one of additive manufacturing’s ambitious space applications. In the future, if their prototype printer can be successful in end-use applications, the team believes it could help reduce the cost and time of space exploration by conducting repairs that do not need additional mission launches.

Serving Aerospace For Decades

We have been serving the aerospace community for the last three decades. For prototyping and other 3D printing requirements, come to your trusted 3D printing company, 3D Composites.