Different Ways To Get The Perfect Finish

PETG is the most famous and used copolymer in the world of 3D printing. PETG stands for polyethylene terephthalate (PET) plastic enhanced with glycol (G). The addition of glycol makes the base PET significantly less brittle and easier to use.

One of the reasons why PETG is used in 3D printing instead of PET is because during overheating, PET becomes cloudy and fragile, which is unfeasible for use with a 3D printer FDM / FFF, a problem that does not happen to PETG because it contains glycol. It is also more durable thanks to its greater resistance to wear and corrosion to oxidizing agents, aspects that are combined with a high resistance to impacts.

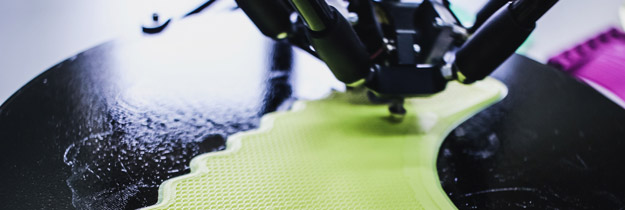

PETG smoothing is a great way to reduce layer lines and deformities in a print. Smoothing results in a more visually-pleasing part. PETG is a very popular filament in the 3D printing community. It’s strong, flexible, and durable, making it a great filament choice for a variety of applications.

What are the common methods for smoothing 3D printed parts:

Sanding is one of the most common ways as it works well on all kinds of filament. It eliminates protrusions on a part, like support marks and zits, as well as reduce the appearance of layer lines. But it can be time-consuming if the part is very large or intricate. Starting with a low grit sandpaper, you can sand the object gradually in even and circular motions until you progress to use the larger grit sandpaper. Here, sanding with water helps to prevent clogging.

Another way is using a polishing compound to smooth PETC prints which enhances the effects of sanding and further reduces the layer lines. Polish may not stick well to the part unless it is adequately sanded. Liquid metal polishes work well on most brands of PETG. Use a soft cleaning cloth with a small amount of polish and rub it on the entire part until it is completely absorbed. Use another cloth and buff to a shine. The disadvantage is needing to use force to rub, which may not be suitable for more fragile parts.

Coating your PETG print is another great way to smooth the surface and to hide deformities. Like with PLA and ABS, epoxy resin is a popular substance for coating PETG prints. Depending on your choice of epoxy, the results can be satisfying. XTC-3D is quite a popular choice of epoxy for 3D printing. It flows smoothly over the part and won’t show brush strokes as easily. It also provides a glossy finish once it’s applied, so you might not need to continue sanding after applying the epoxy. However, you need to prepare the epoxy-resin mix, then carefully apply it to the print with a small brush.

Heat treatment is a viable option for smoothing PETG parts. You’ll need a heat gun with very precise temperature control to do this. Recommended temperature is normally around 250 °C or else it can be difficult to heat treat your part without ruining the print. The idea of heat treatment is to melt a very thin layer of the print’s surface material, removing the layer lines and fill in any undesirable gaps. The result should be a smooth, professional-looking part.