3D Printing Parts That Breathe

3D bioprinting body organs may now look doable as advances in technology make mention those parts that have seen printing already – eyes, skin, heart, bone, among others. However, the more challenging aspect is how to print artificial versions of the body’s complex vascular networks, which mimic our natural passageways for blood, air, lymph, and other vital fluids.

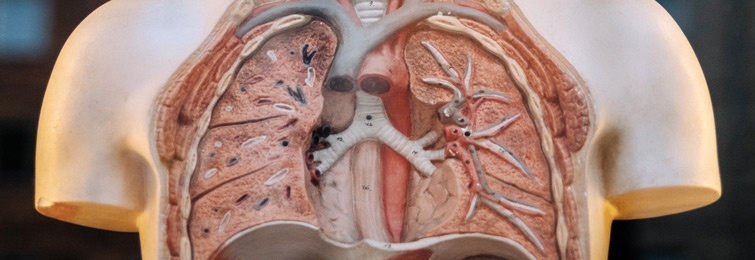

Of late, scientists from the Rice’s Brown School of Engineering have already successfully printed the complex vasculature that can supply nutrients to densely populated tissues, such as the lungs. The team is the first to develop bioprinting technology that addresses the challenge of multivascularization in a direct and comprehensive way. They know that the vascular networks, like the lung’s blood vessels and airways, and the bile ducts and liver blood vessels are interpenetrating networks. They are physically and biochemically entangled, and their architecture is intimately related to tissue function.

SLATE, which stands for “stereolithography apparatus for tissue engineering”, was developed by the scientists which prints one layer at a time from a liquid pre-hydrogel solution which, when exposed to light, solidifies. They tested a lung-mimicking structure, complete with airways and blood vessels, that held up to recreate the breathing process.

What is the impact of creating functional tissue replacements in the medical field?

For one it is a high scientific priority because of its potential impact on organ donations. In the US alone there is a shortage of organ donors; at least more than a hundred thousand patients are on the transplant waiting list. Furthermore, there is the danger of organ rejection for even a successful transplant procedure. Bioprinted organs should be able to address the shortage of organs and the risk of organ rejection.

Reprinting human organs has other potential uses apart from as transplants. Scientists are using 3D printed organs to better understand how they are affected by cancer.

3D Printing Possibilities in Seattle

While 3D printing bio-organs are the next best possibility in some future time, our team at 3D Composites Seattle can be approached for your other immediate 3D printing needs. Contact us and let’s talk ideas.