Nanotechnology is a special name for technology that is small in a big way. This is where we start manipulating matter at an atomic level, creating machines with components mere atoms in width. For a long while, nanotechnology was the domain of the future. Today, however, our 3D printing company in Seattle is pleased to see 3D printing help bring nanotechnology into the modern day.

A group called Nanoscribe has made their Photonic Professional GT system commercially available. This machine is capable of creating objects that are as large as the resolution on most conventional 3D printers. It is with this machine that they are able to print out a miniature model of the Eiffel Tower that stands a mere centimeter tall, with a resolution of 1/1000th of a centimeter. This technology is giving scientists the ability to create sophisticated nanotechnology models more quickly and easily than ever before. The printer represents a great step forward in science and the 3D printing world.

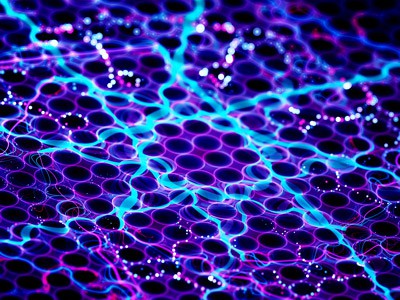

“Nanoscribe‘s technology for the fabrication of three-dimensional micro- and nanostructures in photo-sensitive materials is based on “direct laser writing”, i.e., a non-linear two-photon absorption process. Many resins that polymerize when exposed to UV-light can undergo similar chemical reactions when two photons of near-infrared light are absorbed simultaneously. A necessary condition for this effect to occur is a sufficiently high light intensity that is provided by an ultrashort pulse laser. Typically, the laser is focused into the resin and the two-photon polymerization (TPP) is triggered only in the focal spot volume. As 3D analogon to a pixel, the volume counterpart is called voxel.”