Designing Without Limits There’s a new 3D printer specifically developed to meet…

Not Just Another 3D Printed Bike: It’s A Sustainable Bike

Looking At The Bike Of The Future It started when the German…

Light Rays 3D Print Amazing, Tiny Glass Objects

Useful Applications For Glass Geometries Over at UC Berkeley in California, developers…

Amazing 3D Printed Alloy is NASA’S New High-Performance Metal

Towards High Performance Aerospace Systems The US National Aeronautics and Space Administration…

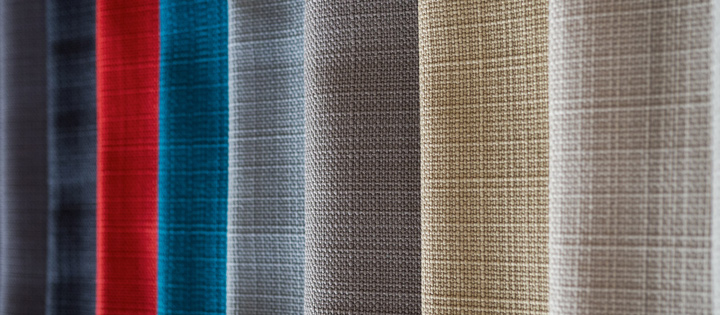

Luxury Car Manufacturer Commits to 3D Printing

Luxury Car’s “Dream Factory” To Lead The Way Bentley, the British manufacturer…