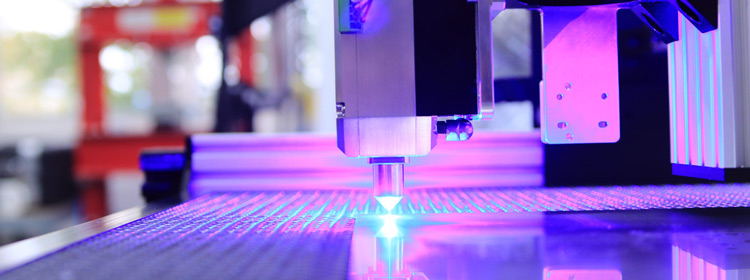

Prototyping For Space And Beyond AML3D is Australia-based and a renowned metal…

How 3D Printed Aids Can Save Cost In Education

Helping The Teacher To Engage Students Did you know that teachers who…

Bioprinting New Technology May Create Living Brain Cells

Advancing Bioprinting How did a team of scientists from the University of…

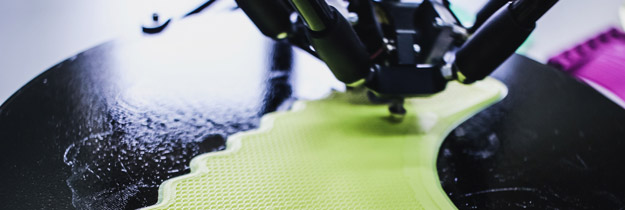

How Binder Jet 3D Printing Can Restore Our Threatened Coral Reefs

Mimicking The Toughness of Corals The value of coral reefs in our…

Maintenance Made Easy By 3D Printing Design

3D Print-Designing A Window For Added Value There are design methods that…