These cylindrical pieces were designed to work as part of an end-of-arm…

News

The Advantages of using ABS in 3D Printing

What’s ABS and what can it do? ABS is acrylonitrile butadiene styrene,…

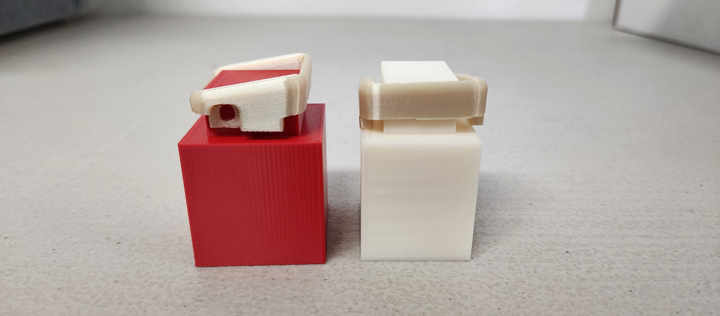

Quality Inspection Blocks

We printed some blocks that are making quality inspection a breeze. We…

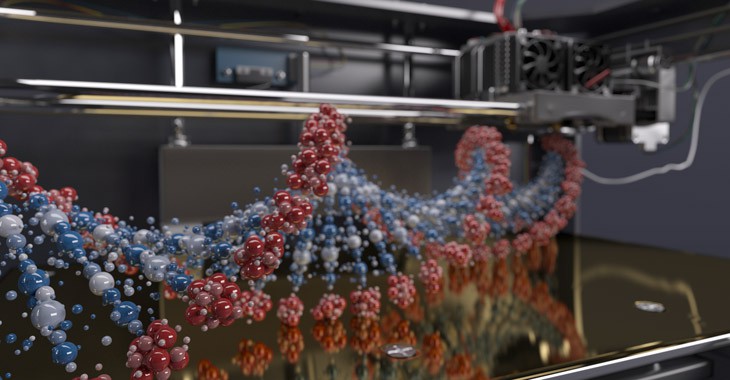

New 3D Printer For The Design and Fashion Industry

Designing Without Limits There’s a new 3D printer specifically developed to meet…

Not Just Another 3D Printed Bike: It’s A Sustainable Bike

Looking At The Bike Of The Future It started when the German…