The Milestones in the 2000s Now we continue on with the remarkable…

News

How 3D Printing All Began: Timeline of A Revolution

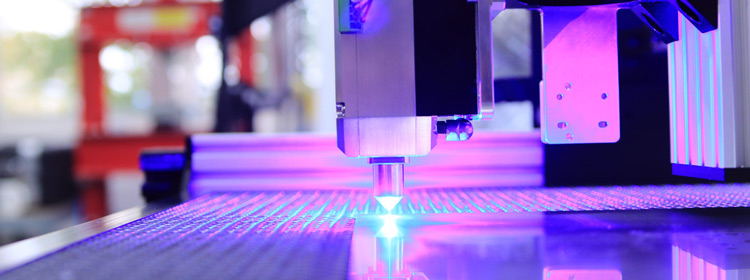

The History of 3D Printing 3D printing technology was first called Rapid…

Understanding What 3D Printing Is About

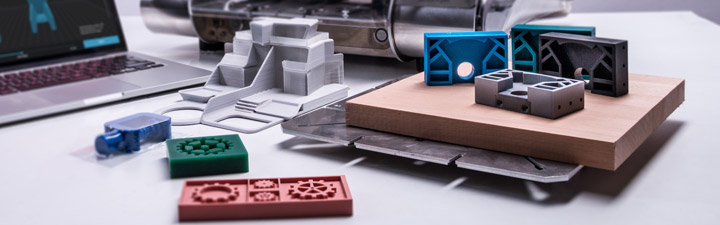

What is 3D Printing Technology? 3D printing is a technology that brings…

Robotics Made Easy with 3D Printing in Seattle

What You Can Get Out of 3D Printing Your Robot If you’re…

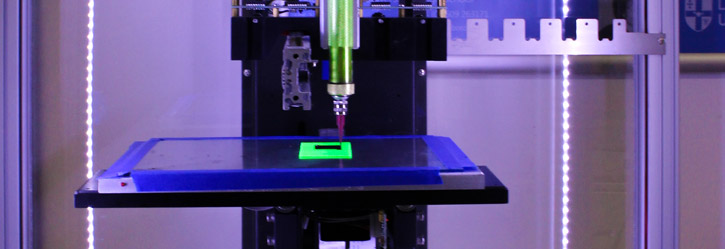

Robotic End-of-Arm Tooling in Ultem 1010

These cylindrical pieces were designed to work as part of an end-of-arm…