Types of 3D Printing Technology

3D printing technology comes in different types. From the most common fused deposition modeling (FDM), there are others – stereolithography, selective laser sintering (SLS), digital light processing, and more. These processes all utilize additive manufacturing differing in several considerations – print quality and print speed, printer capability and printer cost, practicality, and user expectations.

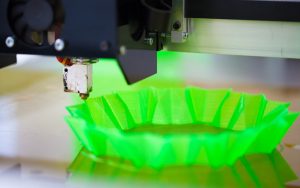

Fused Deposition Modeling

The most common type of 3D printing today is the fused deposition modeling (FDM) type. 3D printers that run on FDM Technology build parts layer-by-layer from the bottom up by heating and extruding thermoplastic filaments. As FDM can print very intricate objects, it’s commonly used by engineers to test parts for fit and form. FDM is also used to produce end-use parts, especially small, detailed parts and specialized manufacturing tools.

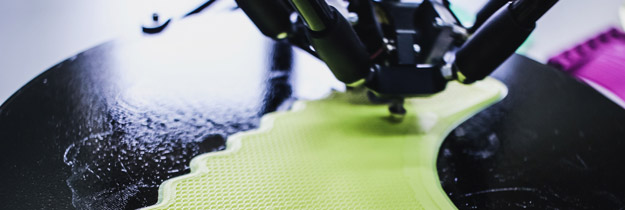

Stereolithography

Another 3D printing application is stereolithography (SLA), which uses photochemical processes, involving fast prototyping. Accuracy and precision are very important. It can produce objects from 3D CAD data (computer-generated) files in just a few hours. Printers that use this technology produce unique models, patterns, prototypes, and various production parts by converting liquid photopolymers into solid 3D objects.

Selective Laser Sintering

Selective laser sintering (SLS) melts nylon powders into a durable solid plastic. The technique uses high power CO2 lasers to fuse particles together. The laser sinters powdered metal materials (others are white nylon powder, ceramics, glass). The finish is not smooth but very functional; useful for prototype designs with hinges and “snap-fits.” It’s perfect for fully-functional, end-use parts and prototypes that are durable and highly precise.

Digital Light Processing

Digital light processing (DLP) is the oldest of the 3D printing technologies. It hardens polymers using a light projector, rather than a UV laser. Yet, it allows an entire layer of an object built at once, increasing print speed. It is robust and produces high resolution models every time. It’s also economical, using cheaper materials for complex and detailed objects. It also reduces waste, and keeps printing costs low.

Learning More About 3D Printing

There are other types of 3D printing processes. If you want to learn more, please feel free to contact us or browse around our website.