What’s FDM?

FDM is Fused Deposition Modeling, a widely used technique of 3D printing. It’s the fastest, most affordable way to create models. The printer uses a thermoplastic filament; at melting point, the material is extruded through a nozzle layer by layer to produce your 3-dimensional object. FDM is an additive manufacturing technology and used for modelling, prototyping, and production applications.

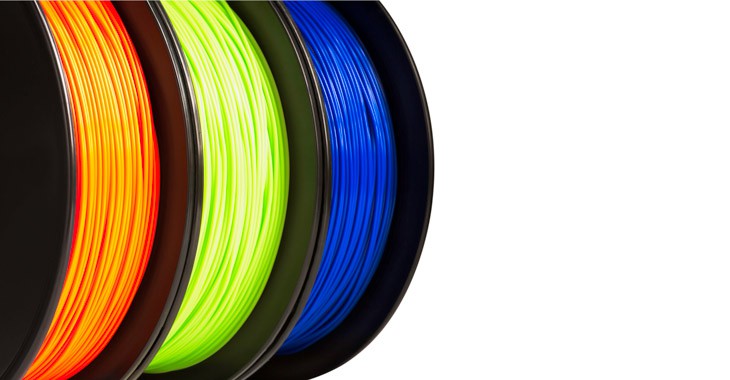

The process of FDM is versatile. Once a software design is made, the printer goes to work. The heated material is extruded thinly, horizontally and vertically, and cools and hardens from the bottom up as your base or platform is lowered in calculations until you see your finished 3D object. The process can use a variety of thermoplastic materials, like acrylonitrile butadiene styrene (ABS), polycarbonate (PC), Polylactic acid PLA, Polycarbonate PC, Polyamide PA, Polystyrene PS, Ultem 9085, and ASA, among many others. These materials are highly resistant to heat and can withstand chemical and mechanical stresses. ASA is UV-stable and fade-resistant.

Seattle 3D Printing Company uses FDM

We have been the choice of our aviation and automotive clients in the past 30 years for their rapid prototyping needs. Our FDM process can print highly detailed and complex designs of varying standard sizes using any material of your option in our materials list. We also print end-use parts and specialized manufacturing tools especially for the food industry, pharmaceutical and medicine sectors.

Drop by 3D Composites, your 3D printing company in Seattle, for your prototype model or for short run rapid manufacturing at a relatively affordable cost using FDM – the best foundation for your idea.