Who uses 3D Printing?

Let’s look at just three of the many industries that resort to the invaluable help of 3D printing.

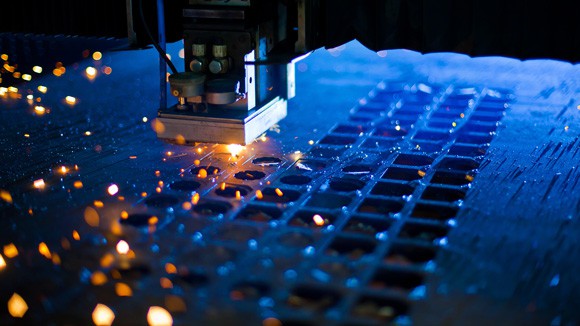

The automotive industry is a big customer for 3D printing and definitely has more applications than in any other sector. It puts automotive designers and engineers on the fast track to achieving their goals. It enables the auto industry to experiment and innovate without tremendous expense and time- consuming production processes. Consider a car’s many fabricated parts for 3D printing, from the littlest screw to its engine motor to its metal body, it might just be the car of the future.

On the one hand, the aerospace industry’s innovators utilize 3D printing to a great extent as well, going beyond prototyping into production applications. Using high-strength thermoplastics, machining costs and time-consuming manufacturing drop drastically. Typical applications of 3D printing for the aerospace sector include engines, turbine parts, assemblies, and cabin interiors. Remarkably strong and lightweight, these technology-printed parts contribute to decrease fuel consumption and CO2 emissions of aircrafts.

Now, can you imagine a whole house built from the ground up via 3D printing? The architectural sector have been using models produced by 3D printing to help their clients visualize designs and determine plan viability and merits. The technology improves the quality of architectural models. Experts say that via 3D printing and prototyping not only building properties is possible but whole communities as well.

Your Industry is Our Concern

3D Composites is your industry-friendly 3D printing needs provider here in Seattle. We count the automotive, aerospace , and the architectural industries as valued clients. We also cater to the printing needs of the military, engineering, medicine, food, and the education sectors among others. Our philosophy is to continuously improve product quality and customer satisfaction.