The Milestones in the 2000s Now we continue on with the remarkable…

Robotic End-of-Arm Tooling in Ultem 1010

These cylindrical pieces were designed to work as part of an end-of-arm…

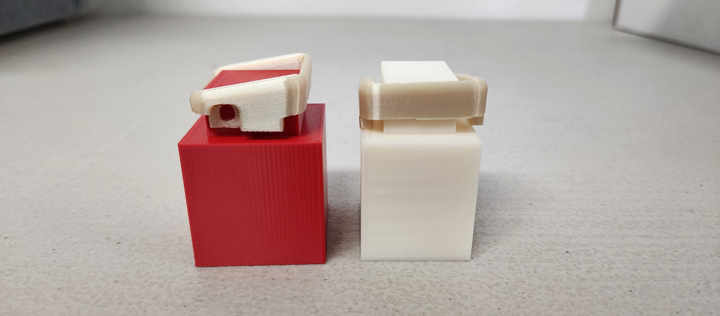

Quality Inspection Blocks

We printed some blocks that are making quality inspection a breeze. We…

Full Service Manufacturing with Cargo Signal

This past month 3DC had the opportunity to combine each of our…

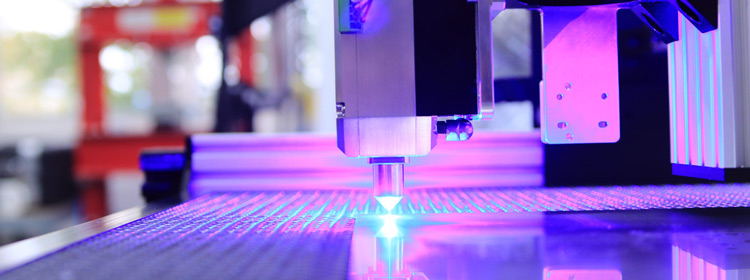

Customize It with Laser Cutting & Engraving

Additive manufacturing excels when paired with a technique that can make it…