This past month 3DC had the opportunity to combine each of our main services to show how our shop works to create a final product. When Seattle based cargo tracking company Cargo Signal came to us with a design that they needed manufactured for a short production run, we knew we could do the job!

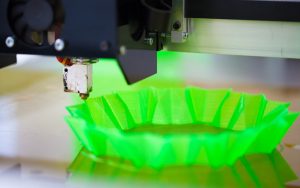

Cargo Signal’s prototype design was to create an encasement for their new tracking device. Building on their idea, our engineering team was able to design an FDM tool that would be 3D printed and used for multiple pulls on our thermoformer. Because thermoforming requires plastic to be heated up to high temperatures, we printed the tool in Ultem 9085, for its thermal resistance and strength.

The body of the parts were thermoformed out of ABS plastic sheets in sets of eight and then our CNC machinists cut them to their final shape. This way we were able to utilize the most space out of the ABS sheets to try and cut down on waste. The finishing touch was to laser engrave each part with the Cargo Signal logo.

“Thanks for the great work, your cases are a big hit…They came out amazing.”

– Paul Nicholls, Cargo Signal

We produced over 1000 cases for Cargo Signal so far with more to go! Our range of services gives our customers maximum customization for their designs and ideas. Click here to learn more about the different services offered by 3D Composites and let us transform your ideas into reality.