Market research has shown that 3D printing is expected to have a…

Did You Know?

The Positive Environmental Impact of 3D Printing

Additive manufacturing has the reputation of being more ecologically friendly than traditional…

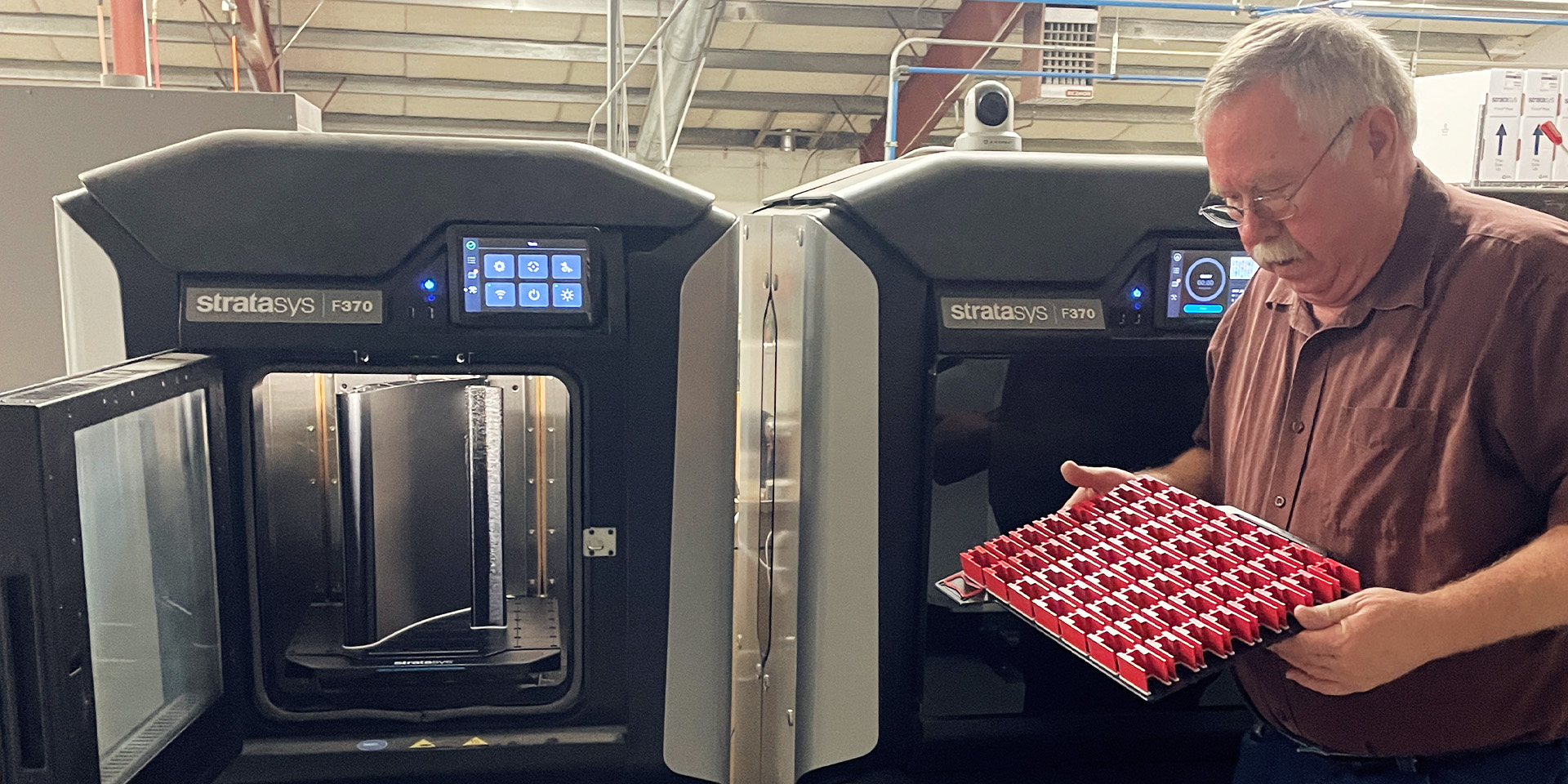

Working with Stratasys

This year we have been working with Stratasys to get started with…

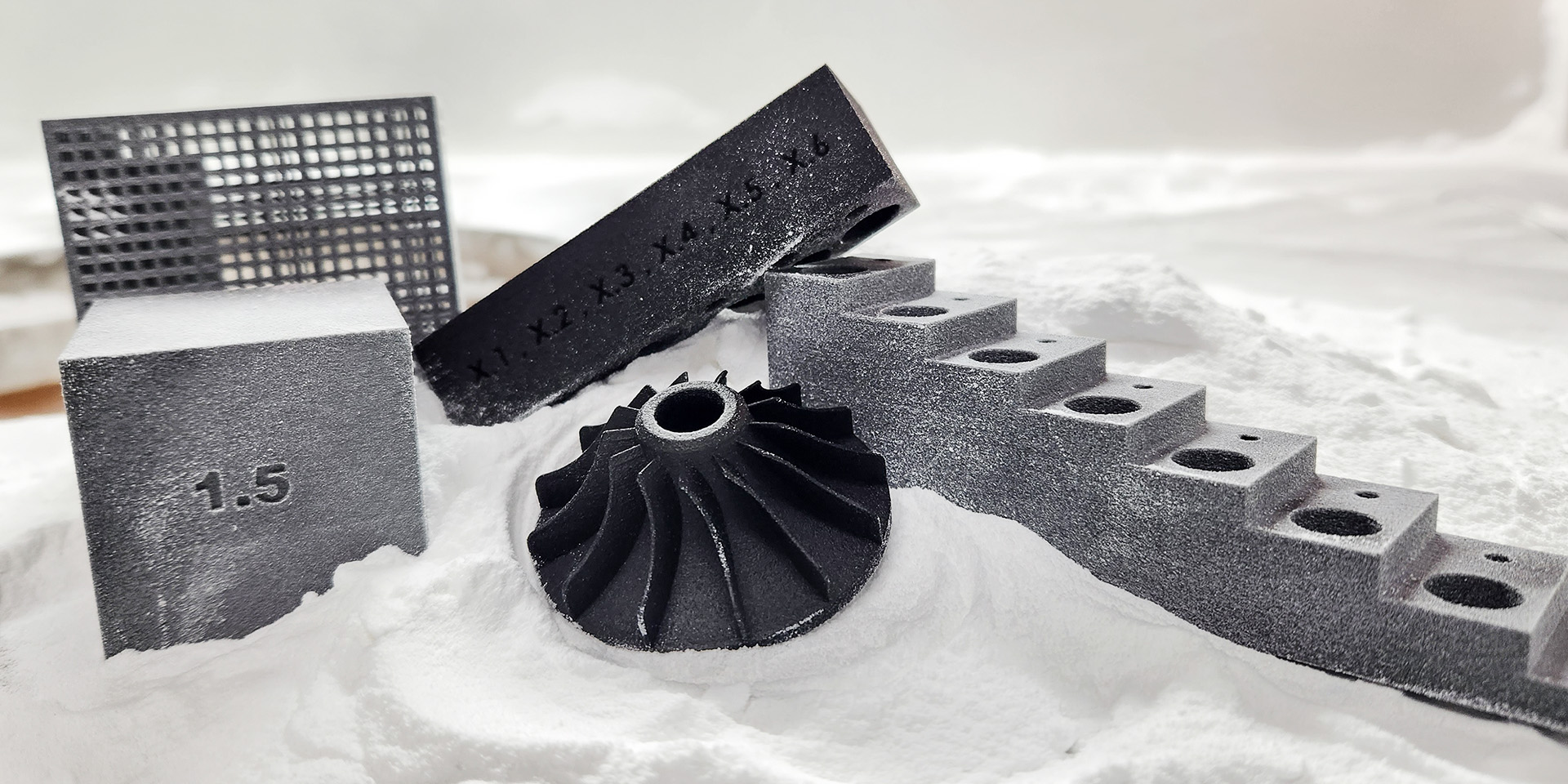

SLS, SLA, or SAF? Comparing 3D printing methods

There are many different 3D printing processes that have been developed in…

Additive Manufacturing Outlook for the New Year

What 3D printing process is best for your industry? Whether you are…